Real Time SPC

ÇÖZÜMLER

NEXT LEVEL AUTOMATED PROCESS MONITORING IN REAL-TIME

Act. Monitor, respond, and deliver immediate quality and process monitoring that provides value and efficiency to your organization.

Streamline data automation and analysis in real-time.

As any manufacturer knows, efficiency is key so quality and process monitoring is of the utmost importance. Real-Time SPC Powered by Minitab® makes quality analysis and improvement easy in one convenient and comprehensive solution, while our monitoring and alerts in real-time allow for immediate action when quality varies, saving both time and money.

With 50 years of leading data analysis and process management, why trust your process monitoring with anyone else?

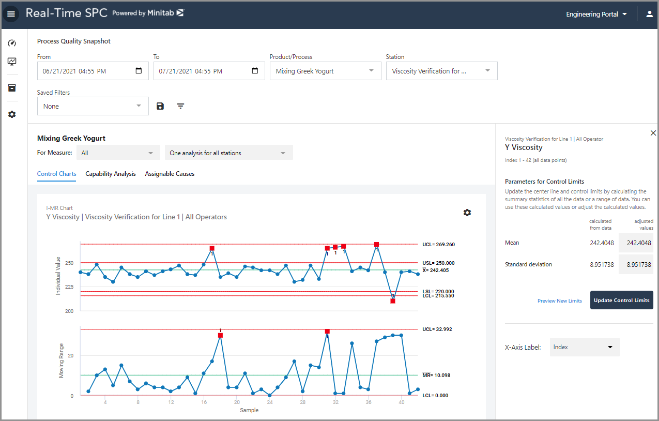

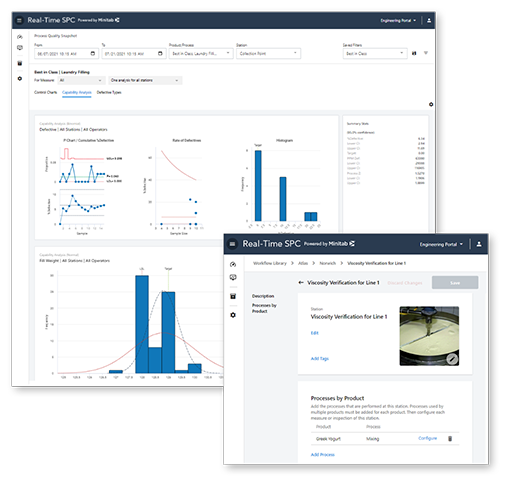

Real-Time Visual Process Monitoring

Centralized, blended, quality data is available for easy, at-a-glance monitoring with real-time control charts and dashboards, including:

- I-MR

- Xbar-R

- Xbar-S

- I-MR-R/S

- P, NP, Laney P’

- C, U, Laney U’

Created by Minitab’s trusted cloud-based software, control charts and dashboards are automatically updated for optimized reporting and insight sharing.

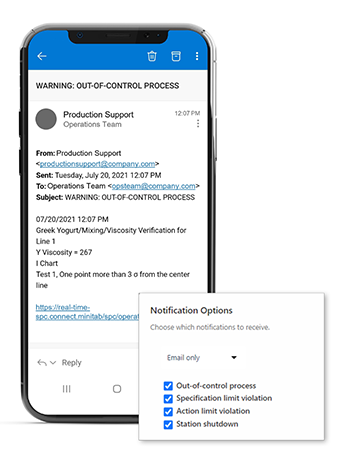

Customizable, Direct, Immediate Alerts

Detect quality issues and prevent waste with immediate process feedback, alerts, warnings, and notifications.

Automatically send customized and useful alerts to the right individuals and teams via email or text enabling teams to respond as soon as possible after issues arise.

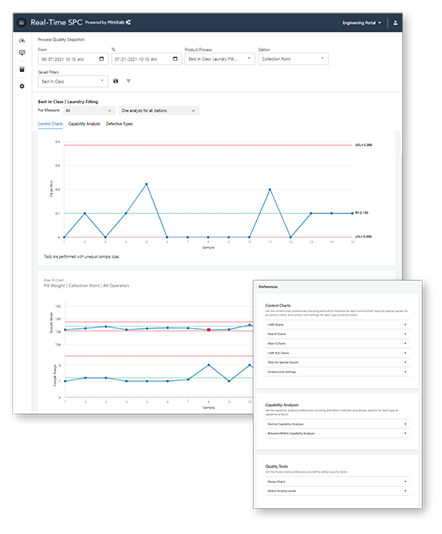

Empowering Operators & Engineers Alike

From operators to supervisors to engineers to management, everyone with responsibility for a process is empowered by Real-Time SPC Powered by Minitab.

Individuals or teams can be assigned access permissions, ensuring the right people can collect data, monitor machines, identify issues, and review performance when needed in every step in the process.

Easy Configuration & Data Collection

Whether your manufacturing environment is simple or complex, centrally managed or strategically placed, Real-Time SPC Powered by Minitab’s set-up and deployment was created with simplicity in mind.

Data can be entered automatically, semi-automatically, or manually to systematically collect and track all relevant data across the process, then monitored in real-time to ensure quality metrics.

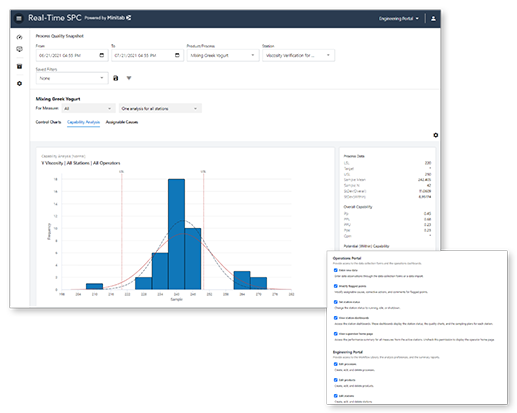

Integrated Ecosystem with Robust Analytics

Leveraging Minitab® Statistical Software with Real-Time SPC Powered by Minitab makes it’s easy to solve your toughest challenges and perform further root cause using statistical analysis including predictive analytics and machine learning. These deeper insights allow you to deliver greater value and optimize your manufacturing processes.

Harness your processes with Minitab in real-time

For 50 years, Minitab has been the leading software for data analysis and quality improvement.

Real-Time SPC Powered by Minitab has the real-time capabilities and trusted analysis you need to take your process monitoring to the next level all in one convenient and comprehensive solution.

Value in Real-Time SPC

We all strive for quality and perfection in our production processes. Monitoring processes from multiple data sources in real-time and having immediate alerts when quality varies can help you and your team quickly identify issues and remedy them.

Real-Time SPC Powered by Minitab allows for immediate action saving both time and money, and reducing waste areas like scrap, rework, and under-performing machinery, which ultimately improves ROI.

Defining Statistical Process Control

Statistical process control (SPC) is a standard methodology for measuring, monitoring, and controlling quality during a process. With a focus on improvement for maximized efficiency, reduced waste, and early detection of issues, SPC’s key tools like control charts and capability analysis are often used in the manufacturing industry.

Licensing

To get information for Licensing and Pricing, please contact us by sending an e-mail to [email protected] or by dialling +90 312 210 13 44.